LIGHT TIGHTNESS: Foils of opaque materials (B, C, Ge, Si have low opacity) over 2,000 angstroms in thickness are guaranteed to have a light attenuation of 105 (optical density 5.0) or greater. Because most foils are made by thin film processes, these can only be made entirely free of pinholes by using special processes. Many of the thicker foils are rolled and are light-tight. Typical foil has a light attenuation of 105 to 107 and we are committed to making foil with sufficient light-tightness to meet any experimental requirement. On request, the light leakage of foil can be measured and reported to a sensitivity of 1 part in 109 (O.D. 9). Foils sold as vacuum tight have no He leaks larger than 1 x 10-7 std cm2/sec.

MECHANICAL STRENGTH: We make no claims covering the ability of these foils as windows to support atmospheric pressure. This depends on many factors. We will provide best-effort guidance upon request. Foils as thin as 0.1 micron are used as windows between 10-5 and 10-9 torr vacuums. Foils used as atmosphere to vacuum windows require exceptionally carefully designed mounts. Even though a foil has no leaks, it may not be strong enough to support 1 atm of pressure over a large aperture. Lebow Company can supply mounted and tested vacuum windows.

MOUNTING: All foils are quoted mounted on suitable rings (see MOUNTING RINGS in section 7, PART NUMBERS, for Lebow standard ring specifications) with vacuum-compatible adhesives or epoxies. No adhesive of any kind is used on foils under 0.1 micron thick. A range of vacuum compatible adhesives and epoxies, as well as adhesive-free UHV mounts are available to meet special needs. The engineers at Lebow Company will gladly assist you in designing suitable foil mounts for your application.

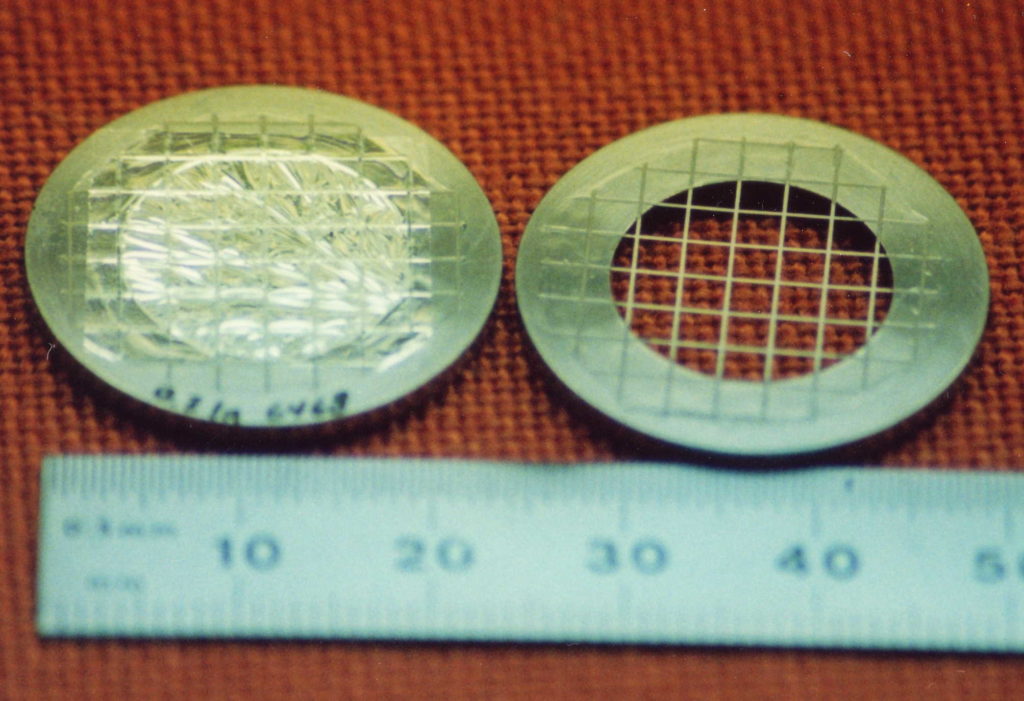

SUPPORTS: All foils are available supported for additional strength but supports are optional (all foils made unsupported except for Mg, Pb, Zn and Fluorides) even for foil as thin as 20nm.

Standard supports are mesh and/or Parylene N. Parylene C & D and other plastics, Polycarbonate (Lexan®), PET (Mylar®), PTFE (Teflon®) and Polyimide (Kapton*), are also stocked in a wide range of thicknesses.

SUPPORT – MESH:

Standard:

| PITCH | LPI | SPACE | BAR | TRANSMISSION | MATERIAL |

| 0.36mm | 70 LPI* | 340µ | 18µ | 86% | 5µ Ni, Electroformed |

Other Stock – Mesh:

| PITCH | LPI | SPACE | BAR | TRANSMISSION | MATERIAL |

| 33µ | 750 LPI* | 25µ | 10µ | 55% | 5µ Ni, Electroformed |

| 86µ | 300 LPI* | 66µ | 19µ | 61% | 5µ Ni, Electroformed |

| 86µ | 300 LPI* | 66µ | 19µ | 61% | 5µ Cu, Electroformed |

| 0.13mm | 200 LPI* | 112µ | 14µ | 78% | 5µ Ni, Electroformed |

| 0.36mm | 70 LPI* | 344µ | 19µ | 86% | 5µ Cu, Electroformed |

| 0.65mm | 40 LPI* | 0.48mm | 0.16mm | 56% | 5µ Ni, Electroformed |

| 0.85mm | 30 LPI* | 0.80mm | 0.043mm | 90% | 5µ Ni, Electroformed |

| 1.04mm | 25 LPI* | 0.94mm | 0.079mm | 85% | 5µ Ni, Electroformed |

| 1.27mm | 20 LPI* | 1.18mm | 0.092mm | 86% | 5µ Ni, Electroformed |

| 1.6mm | 15 LPI* | 1.56mm | 0.14mm | 85% | 5µ Ni, Electroformed |

| 2.5mm | 10 LPI* | 2.37mm | 0.17mm | 87% | 5µ Ni, Electroformed |

| 2.5mm | 10 LPI* | 2.37mm | 0.17mm | 87% | 20µ Stainless, Etched |

*lines per inch

High attenuation mesh – Wavelength independent attenuation for high flux applications

| MESH TRANSMISSION | PITCH | LPI | HOLE | MATERIAL |

| 1.4% | 0.56mm | 45 LPI | 0.18mm | 2 layers of 12% transmission |

| 12% | 0.56mm | 45 LPI | 0.18mm | 0.2mm 316 stainless steel |

| 25% | 0.394mm | 64 LPI | 0.23mm | 0.2mm 316 stainless steel |

| 50% | 0.73mm | 34 LPI | Space 0.53mm | 0.2mm Expanded 304 stainless |

| Bar 0.2mm |

Transmission is nominal. Actual transmission will be labeled.

SUPPORT-PARYLENE N:(-C8H8-), density 1.1

Stock Thicknesses:

| 0.1µ | 1.35µ | 5.0µ | 15.0µ |

| 0.2µ | 1.5µ | 6.0µ | |

| 0.5µ | 2.0µ | 7.5µ | |

| 0.75µ | 2.5µ | 10.0µ | |

| 1.0µ | 3.0µ | 13.5µ |

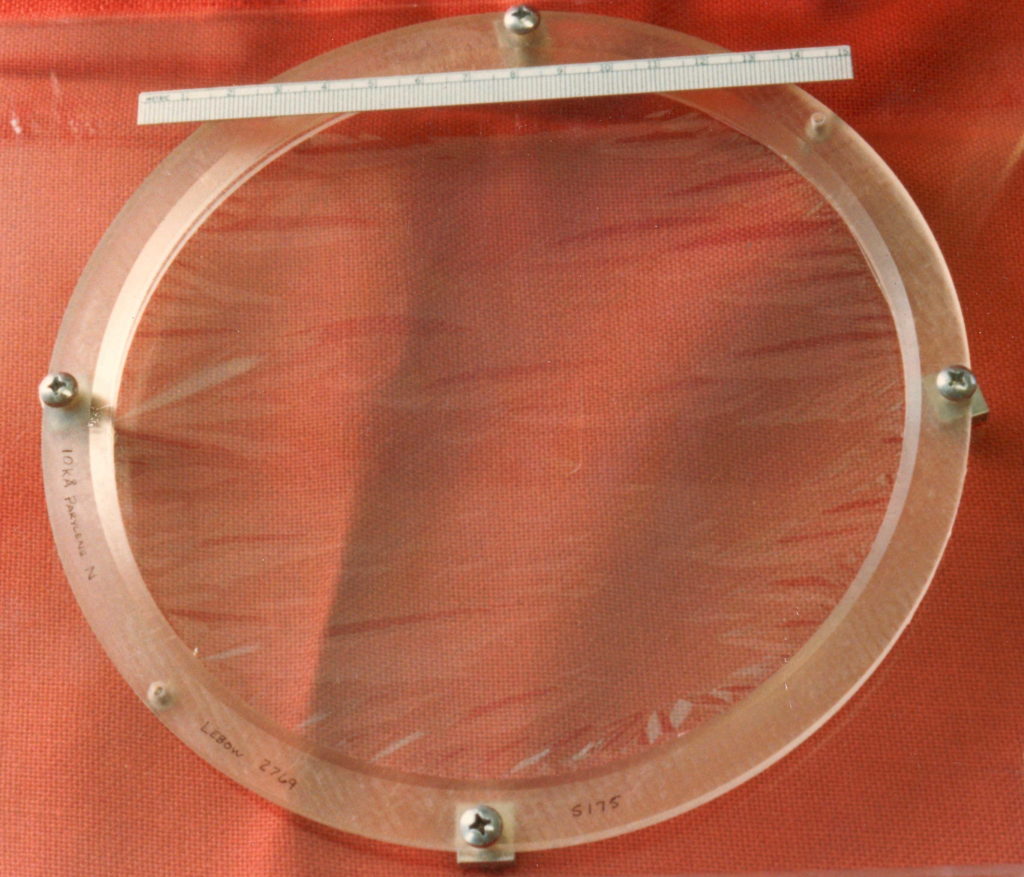

Lebow Company is capable of making very large Parylene N filters. The pictured 1.0 micron Parylene N filter is 150mm diameter.

TENSIONED FOILS

Occasional experiments must focus on the entire foil area, reflect a beam off the foil, or involve ultrafast events over the entire foil area. These experiments will benefit from tensioned flat foil. Tensioned foil for most materials over 0.5µ thick can be made. This foil is significantly more costly and requires epoxy mounting on special rings.

PURITY:

The purest practical material is used in all foil and the purity for total metal impurities is indicated. Detailed material pedigrees and lot or individual foil analysis are available at a nominal fee.

THICKNESS TOLERANCE:

±10% standard; closer tolerances are available upon request. We can supply exact lot or individual foil measurement of the mechanical thickness, weight/unit area or the apparent thickness by alpha energy loss as required for a nominal fee.

PART NUMBERS:

Our part numbers are descriptive, therefore, long, allowing an accurate identification of the required foil assembly.

Example: 0.5 (thickness)-Ti (material)-P1k (support)-L1.34 (mounting/size)

THICKNESS in microns (0.5)

1 micron (µ) = 0.001mm = 1,000nm = 10,000 Angstrom (Å).

0.001 inches = 25.4 microns

MATERIAL indicated by chemical symbol for the element (Example: Ti).

SUPPORT:

0 – Unsupported

P – Parylene-N supported, 0.1µ (Example: P1K)

M – Nickel Mesh, 5 microns thick, 86% transmission, 36 micron pitch (70 lines/inch). Cu mesh and other mesh pitches are available from stock.

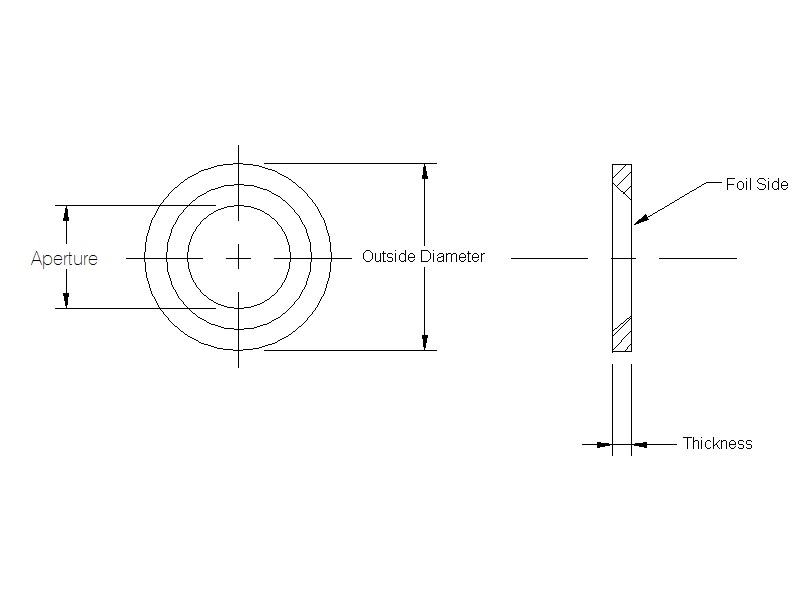

MOUNTING/SIZE:

Specifies the mounting ring (L1.34, Lebow 1.34cm I.D.) and foil size. Foils are mounted to cover only the unsupported area only and needed margin for adhesive on Lebow rings, customer designed rings, or customer supplied rings. Lebow is able to fabricate rings to customer drawings and regularly supplies complete foil assemblies for inclusion in instruments.

L – LEBOW STANDARD machined rings with beveled edge hole, 304 stainless steel, without mounting holes.

| RING SIZE | APERTURE | OUTSIDE DIAMETER | THICKNESS |

| L0.5 | 5.0mm | 17.0mm | 1.5mm |

| L1.0 | 10.0mm | 17.0mm | 1.5mm |

| L1.34 | 13.4mm | 22.3mm | 1.7mm |

| L1.5 | 15.0mm | 25.0mm | 1.7mm |

| L2.0 | 20.0mm | 30.0mm | 1.7mm |

| L2.54 | 25.4mm | 38.1mm | 1.7mm |

| L3.0 | 30.0mm | 40.0mm | 1.7mm |

| L3.27 | 32.7mm | 45.0mm | 1.7mm |

| L4.0 | 40.0mm | 60.0mm | 1.7mm |

Tolerance: +/-0.1mm

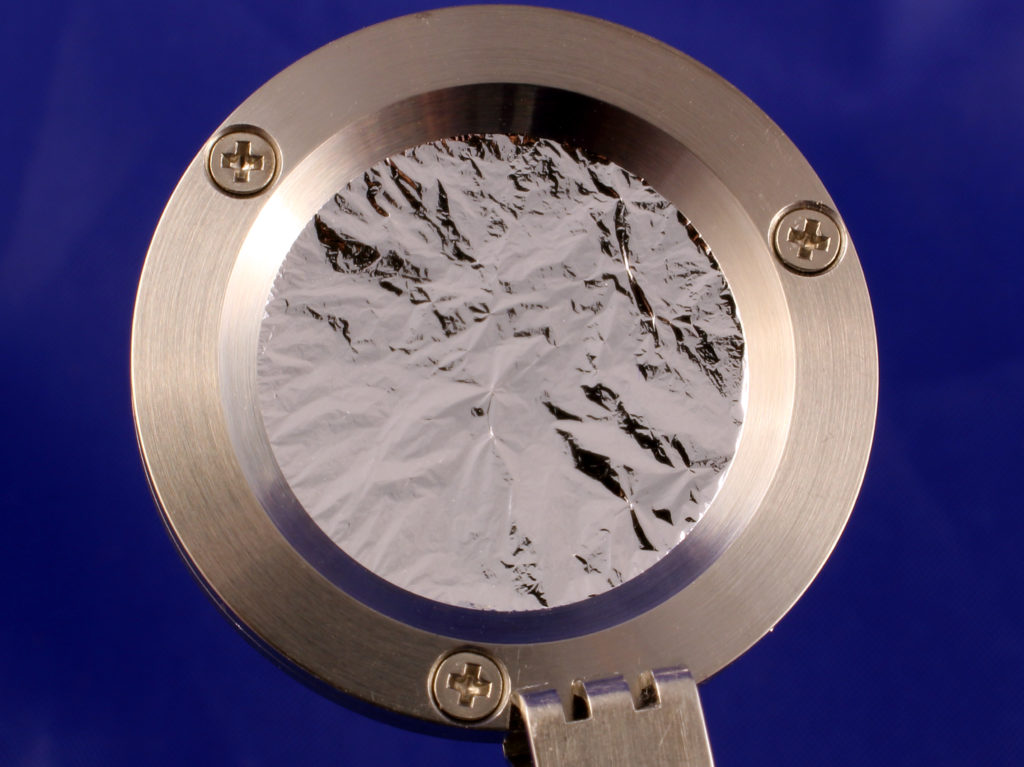

LS-LEBOW STARDARD UHV SANDWICH rings are designed for UHV applications where no adhesives or epoxy can be tolerated. They are made of 304 stainless and baked at 300ºC in high vacuum. LS rings cannot normally be used with mesh supported foil or B, Be, Ge, or Si over about 0.5 microns thick because organic adhesives are required.

UHV Sandwich mounted Al foil. The UHV rings are vacuum baked before mounting the foil at 300ºC and are completely organic free.

| RING SIZE | APERTURE | OUTSIDE DIAMETER | THICKNESS | HOLE CIRCLE | SCREWS |

| LS0.5 | 5.0mm | 17.0mm | 3.0mm | 14.3mm | 2 |

| LS1.0 | 10.0mm | 17.0mm | 3.0mm | 14.3mm | 2 |

| LS1.34 | 13.4mm | 22.3mm | 3.4mm | 19.5mm | 3 |

| LS1.5 | 15.0mm | 25.0mm | 3.4mm | 21.7mm | 3 |

| LS2.0 | 20.0mm | 30.0mm | 3.4mm | 26.7mm | 3 |

| LS2.54 | 25.4mm | 38.1mm | 3.4mm | 34.8mm | 4 |

| LS3.0 | 30.0mm | 40.0mm | 3.4mm | 36.7mm | 4 |

| LS4.0 | 40.0mm | 60.0mm | 3.4mm | 53.4mm | 6 |

C-CUSTOMER supplied mounting rings: Machined rings 0.5mm or more thick with a minimum 5.0mm width for foil bonding are preferred. Rings must be made of stainless steel or other low expansion material if the foil will be heated or baked. Aluminum rings are suitable only for aluminum or similar foil. User supplied rings in quantities of over 10 should be approved before your order is placed. Specify these as C followed by the inside diameter (or diagonal), i.e., C2.54mm or C1inch for a 1 inch customer supplied ring. Extra charges may apply for difficult rings.

V-VAT RINGS to fit VAT 01032-UE(or CE)**-X (X =window) mini UHV gate valves (DIN 25, 40 & 50) with window, edge threaded, are in stock with 10mm and 15mm inside diameter. Adapters, to allow using L1.0 rings in VAT valves, can also be supplied

PACKAGING – Foils are individually packed in plastic vials or plastic boxes. These are reliable shipping containers but are not intended for long-term storage. Most thin metal foils oxidize and all should be stored under an inert atmosphere or vacuum. Readily oxidized materials are shipped under dry nitrogen.

A standard Lebow Company shipping vial containing a mounted filter.

MARKING – All foils are marked on the ring with the foil material and lot number in low volatility ink. Foil rings can be supplied without marking or with scribed markings as required.

PRICE CLASS – This is our method of denoting the fabrication difficulty and is the price indicator.

Class 1 – Economical, readily fabricated. Sizes limited by equipment to 200mm.

Class 2 – Moderately priced, reliably fabricatable. Maximum size 100mm, larger for some materials.

Class 3 – Challenging, can be fabricated into top quality foils. Maximum size, 50mm, larger for some materials.

Class 4 – Difficult materials, the fabrications of which may offer major technical challenge. Our experience with these materials indicates that occasional closed cracks or a tiny patch may be unavoidable. Limited to 15-25mm, occasionally larger.

2 or 3 x Class 4 – Foil requiring extraordinary technology with significant technical risk. This foil is so difficult to make that it is effectively offered on a “Best Effort” basis. The B foil manufacturing process is particularly unstable. Size limits, 10-15mm.

METROLOGY

- MICROBALANCE 30 gm capacity, 1 microgram resolution.

- ALPHA SPECTROMETER .1-10 micron, .05 micron resolution.

- ULTRA MICROMETER 100 micron capacity, 1%/0.02 micron resolution.

- OPTICAL DENSITOMETER 1 part in 109.

RoHS declaration: Our foils do not contain, unless specified as an ingredient, Pb, Cd, Hg and generally contain little or no organics.